Download Full Technical Report Here

Download Full Technical Report Here

Led the design and development of an active airbrakes system for UVA Rocketry’s 2025 IREC entry, enabling precise altitude control for the 10k COTS competition. The subsystem actively modulates aerodynamic drag during flight, addressing variability in motor performance, atmospheric conditions, and manufacturing tolerances.

Oversaw the mechanical, electrical, and software integration of the system, ensuring modularity, robustness, and ease of testing while simultaneously mentoring 29 sub-team members in advanced aerospace engineering practices.

Achieving precise apogee control required an active drag system to modulate descent trajectory while minimizing structural mass. The design needed to be compact, robust, and manufacturable using in-house resources within strict competition timelines. Additional constraints included ensuring dynamic stability, reliable electronic control, and fail-safe mechanisms in the event of servo or power failure.

Variability in launch site conditions—including atmospheric density, pressure, and temperature—required the system to function reliably across multiple flight profiles.

Two actuation strategies were considered: external deployable flaps versus internal retractable petals. Flaps were simpler in moving parts but introduced aerodynamic complexity and risk of structural compromise. Petals, in contrast, stowed within the coupler tube, maintained aerodynamic symmetry during thrust, and distributed drag evenly during the coast phase.

The final design uses three radially-deployed petals aligned with the rocket’s fins, ensuring predictable aerodynamic behavior while minimizing the overall profile.

The petals are actuated by a cam-driven system that converts rotational motion from a high-torque servo into linear extension. This approach was chosen over lever- and gear-based mechanisms due to its combination of compactness, repeatability, and linearity. The cam slots were parameterized and optimized using Desmos to ensure a linear extension rate, simplifying control and simulation.

A spring-powered retraction system provides fail-safe behavior: when electronics fail, petals automatically retract to a neutral position. The retraction torque is adjustable through 3D-printed pre-load disks, allowing precise balancing with the servo torque.

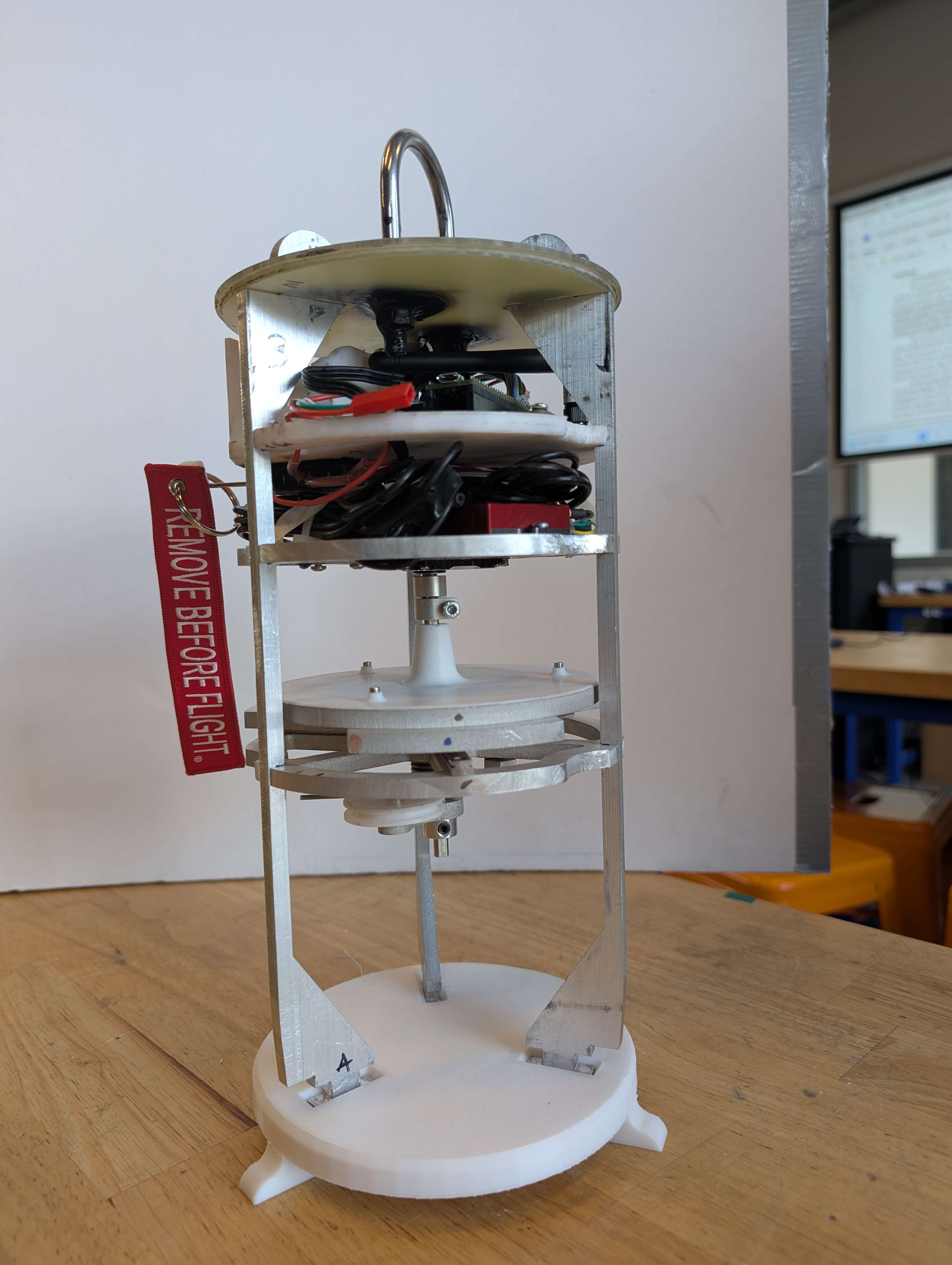

The system is housed entirely within the aft coupler tube. Mechanical components include:

The design was verified through static load calculations and FEA: the stringer assembly has a factor of safety of 6.25 under maximum expected loads (20 lbs at 10g), considering potential shear and tension failure modes.

A custom four-layer PCB integrates IMU, barometer, servo driver, telemetry (LoRa), and microSD data logging. High-current components, including a Sincecam 60 kg servo, are isolated from low-power sensors to maintain stable operation.

Airbrakes deployment is governed by a state-machine with PID control. Transition points are based on IMU acceleration data, barometric altitude, and pre-computed OpenRocket simulations. The system can deploy airbrakes only after motor burnout or a minimum altitude (6,500 ft AGL) per competition rules.

Flight simulations were conducted using RocketPy to validate deployment timing and predict apogee under varying drag conditions. The software logs data to a microSD card and streams telemetry to the ground station in real time.

CFD simulations in ANSYS Fluent were used to generate drag coefficient tables across multiple velocity and altitude conditions. Both stowed and deployed states were modeled to predict the impact on trajectory. Meshes were generated from CAD models and refined to capture pressure contours at leading edges and petal surfaces.

Automated scripts using PyAnsys facilitated drag coefficient extraction for use in flight software, reducing manual error and improving simulation repeatability.

Although environmental factors and last-minute motor changes prevented airbrakes deployment during IREC 2025, the system was fully validated mechanically and electronically. The thorough documentation and simulation rigor contributed to a 1st Place finish in the 10k COTS category.

Key outcomes include:

This project reinforced the importance of:

The cam-driven petal system provides a strong baseline for future iterations, balancing mechanical simplicity, reliability, and flight performance.