Download Poster Here

Download Poster Here

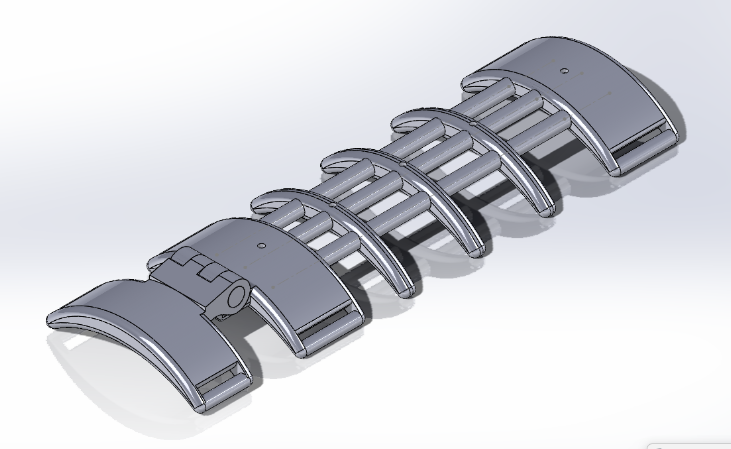

Designed an entirely 3D-printed arm brace with a limited mobility hinge to improve comfort while maintaining steadiness for people with fine motor skill disabilities, such as dyspraxia.

A prototype was designed to test hinge stength and reliability, and a revised design was completed incorperating these results.

Fine motor skill disabilities have limited options for physical assistive devices, and long term wearability and comfort remain largely unadressed.

Early on, the team decided that a way to improve comfort would be to less rigidly fix the hand in place, allowing a user to adjust their hand more easily. The mechanism chosen to achieve this goal was to have the product hinge at the wrist. In order to maintain the steadiness constraint, it was decided that the hinge should only allow the hand to move upward, and would lock the hand in place relative to the arm with any downward pressure. To improve manufacturing accessibility, all parts were designed to be 3D-printed and then assembled by hand without tools. This involved making a smooth but reliable press-fit hinge and pin. The design of the arm attachment points would allow a custom fit to be achieved by changing the dimensions of the rib parts.

Due to time constraints, the product could not be tested by target individuals to gain their feedback. However, other testing verified that the stability constraint was met, and comfort levels from a survey of test users were positive.

This project reinforced the importance of:

This iteration of the arm brace provides a starting point for further improving user experience.